Home of The Shuttle...

Home The Cars The Humor Contact Me

Visitor Number

|

Welcome

to

TurboCelica.com.. Home of The Shuttle... |

Navigation

Menu Home The Cars The Humor Contact Me |

Visitor Number |

Chris' '90 Toyota Celica

All-Trac Turbo (aka "The

Shuttle")

The Water-to-Air Intercooler System

As of Summer 2002, I no longer use this

Spearco WTA IC setup. As of Sept. 2004, the WTA IC, front heat exchanger

and water pump have been sold.

Please do not email me asking whether I

still have them.

As of Summer 2002, I no longer use this

Spearco WTA IC setup. As of Sept. 2004, the WTA IC, front heat exchanger

and water pump have been sold.

Please do not email me asking whether I

still have them.

During Tranny Swap Summer of 2002, I switched to a HKS FMIC As a result, this information is provided for historical reference.

My WTA IC system contains the following components: Spearco WTA IC, custom front radiator (heat exchanger), water pump, temperature gauges, and a 4-gallon reservoir.

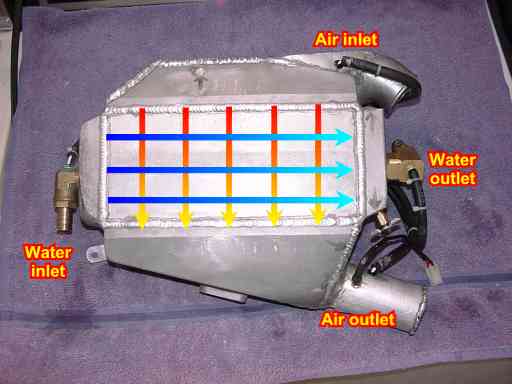

The WTA IC. The intercooler is a Spearco model. In this diagram, water and air flow across the core left to right and top to bottom, respectively. Notice the wiring and probes for the digital IC temp gauges. The petcock is used to bleed air out of the IC.

Temperature Probes. Here are detailed photos of the temperature probes used to monitor both air and water temps across the IC.

|

|

| Overview

(left) and detailed (right) photos of the air outlet temp probes. The long probe is to the IC temp gauge, while the shorter probe is the temp sensor for the Autronic EMS. |

|

|

Here are a couple photos showing a probe both before and after it is mounted into the brass fitting. |

IC Temp Gauges. These are the gauges I use to monitor the temps of both water and air both entering and exiting the IC. With these gauges, there's absolutely NO guessing. They're mounted in the center console, next to the Halmeter AF30 air/fuel ratio gauge. Each gauge is equipped with a three-position switch (the orange goober) which allows switching between inlet and outlet temps and the delta. Obviously, as each medium flows across the IC core, water temp increases while air temps decrease. I purchased these temp gauges from Powerhaus Racing, a Porsche tuner in Temp, Az. back in September 1998, but Powerhaus no longer sells them. The good news is that SP Engineering does sell 'em. Their contact info is on the My Favorite Vendors page.

Custom Heat Exchanger. My WTA system uses a water cooling system that's completely separate from the engine's cooling system. The use 190 deg F water as a cooling medium would make no sense. So, I have a custom radiator which is mounted in the location of a typical FMIC. Here are a few photos of this radiator and it's two 7" Spal fans.

|

|

Click the above photos for larger images.

IC Water Pump and Reservoir. This photo of the rear hatch area shows the IC reservoir and the water pump. The tubing is 1/2" ID nylon-reinforced clear neoprene. On race day, I can easily drain some of the water from the reservoir, and refill with ice. Imagine, 40-45 deg F air entering the engine on a hot 95-100 deg F Texas day. THAT, my friends, is an efficient IC. This reservoir is available for about $100 from BHR Motorsports. Their contact info is on the My Favorite Vendors page.

Discontinued Water Cooler. Prior to the installation of the large 4 gallon fuel cell in the rear hatch for use as the WTA IC reservoir, I had fashioned the following ice chest. Essentially, this was used by filling with ice, and circulating the IC cooling water through the copper tubing. This contraption may look bizarre, but I got the idea from my old hot-rod Mopar days when we used a cool-can, a coffee-can sized version of this ice chest, to cool gasoline before feeding it to the carburetor. It worked well then, and believe it or not, this "cooler" worked great. Immediately after filling with ice, I could easily get 40-45 deg F water out of this "cooler" and into the IC. Talk about heat absorption, it would completely melt 10 lbs of ice in about 15-17 minutes. The major drawback is that I had to frequently drain the melted ice otherwise it would slosh around and spill out of the ice chest since this ice chest was not sealed at the top.

|

|

Return to The Shuttle's home page |

|

|

Return to The Shuttle's Future Mods page |

|

|

Return to The Shuttle's Current Mods page |